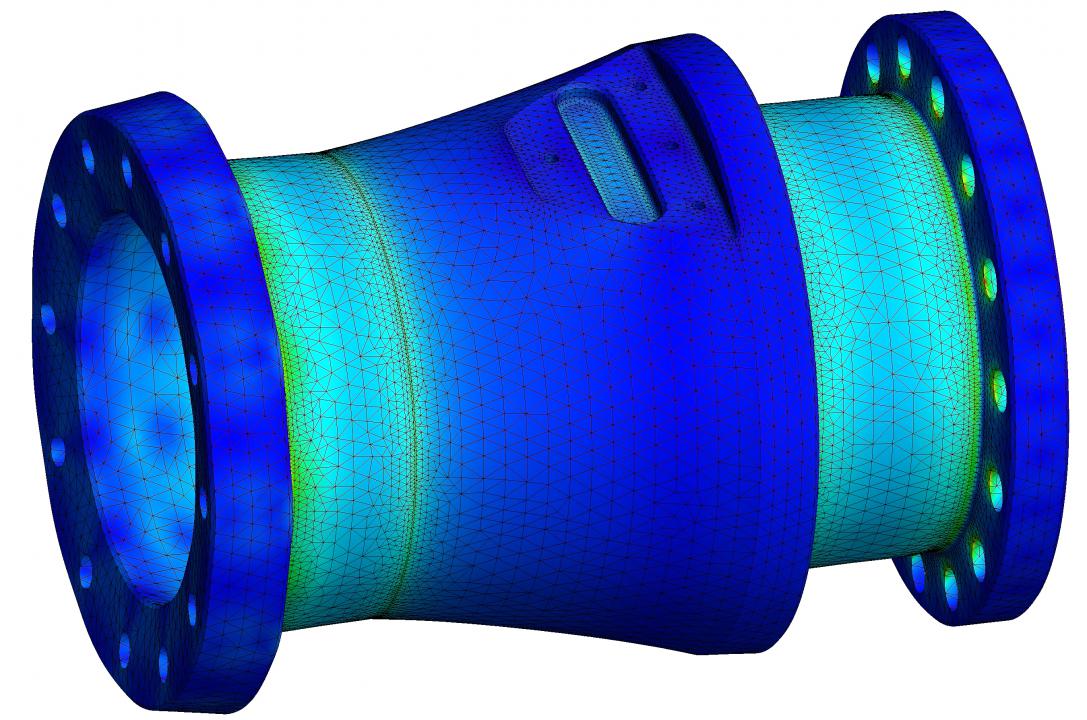

Finite Element Analysis (FEA) Simulation Services

Our NH Based team utilizes the Finite Element Analysis (FEA) in the simulation of any given physical phenomenon using the numerical technique called Finite Element Method (FEM). This technique gives us a practical view of the performance of a given product to reduce the number of prototypes needed. Call our mechanical engineers today to get a quote for an FEA for your mechanical part or product.

FEA's Get You the Product You Want for the Lowest Price

Whether you need a design for an entire assembly or a small part to work with such a device, you're going to want to have that design realized for the lowest cost, especially if you're working at an industrial level. We utilize FEA's to save you money by digitally testing your product for safety and performance defects before it goes into the design stage.

Get the Safest Product for Your Mechanical Designs

While it's important to save money for your mechanical designs, it's far more important to ensure the product ultimately performs safely, especially if that product is to be a passenger vehicle. With safety in mind, you can't afford not to utilize our FEA's to ensure the physical functionality of your product will be up to the greatest safety standard. For this purpose, FEA's are an essential part of the design process for many different industries including:

- Automotive

- Ballistics

- Mountain Resort Rides

- Aerospace industries

- Industrial design

We Pair Our FEA's with CAD Modeling to Ensure the Right Product the First Time

Knowing the physical workings of a device isn't possible without knowing the physical design of that device as well. Fortunately, our NH Based team also provides CAD modeling to conceptualize safe and practical design as well as performance. Call us today to get a quote for any of the services our mechanical engineers offer.